Sợi cation EM-RC01 2.5D

Để hưởng ứng chiến lược quốc gia "carbon kép" và hướng tới phát triển bền vững, năm 2021, công ty đã đầu tư mạnh mẽ, áp dụng thiết bị sản xuất tiên tiến trong và ngoài nước, xây dựng nhiều dây chuyền sản xuất sợi hóa học. Trên cơ sở các loại sợi khác nhau, công ty đã bổ sung các loại sợi chức năng tái chế khác nhau, đáp ứng nhu cầu đa dạng của khách hàng trong và ngoài nước.

In today's rapidly developing field of materials science, modified fibers, as a key element to improve the performance of textiles, are increasingly receiving widespread attention from the market. As a leader in this field, Suzhou Emon New Material Technology Co., Ltd. has greatly improved the performance of modified fibers in multiple key performance indicators through a series of innovative technologies and processes, successfully meeting the increasingly diverse needs of the market. This article will deeply explore how Suzhou Emon leads the innovation of modified fiber technology through physical modification, resource recycling and other means.

1. Comprehensive upgrade of modified fiber performance

During the production process, Suzhou Emon New Material Technology Co., Ltd. pays special attention to improving the performance of modified fibers in terms of hygroscopicity, dyeing efficiency, antistatic properties, and flame retardancy. Through advanced modification technology, the company not only significantly enhances the moisture absorption and perspiration function of the fiber, making it more comfortable to wear, but also greatly improves the dyeing efficiency and color fastness of the fiber, providing designers with a wider space for color selection. In addition, in response to the antistatic needs of modern electronic textiles, Emon's modified fibers exhibit excellent antistatic properties, effectively reducing static electricity accumulation and improving user experience. More importantly, the flame-retardant modified fiber developed by the company can effectively delay the spread of fire in emergency situations, providing a solid guarantee for safety protection.

2. Physical modification: innovative applications of special-shaped fibers

Another highlight of Suzhou Emon in the field of modified fibers lies in its application of physical modification technology, especially the manufacturing of special-shaped fibers. Through precise spinning processes, the company is able to give the fibers unique cross-sectional shapes, such as triangles, multi-lobes, etc. These special shapes not only enhance the optical effects of the fibers, such as producing flash, matte and other visual effects, but also significantly improve The physical properties of the fiber, such as abrasion resistance, tear resistance, etc. This innovation not only adds unique charm to end products, but also broadens the application fields of modified fibers, ranging from fashion apparel to functional outdoor equipment.

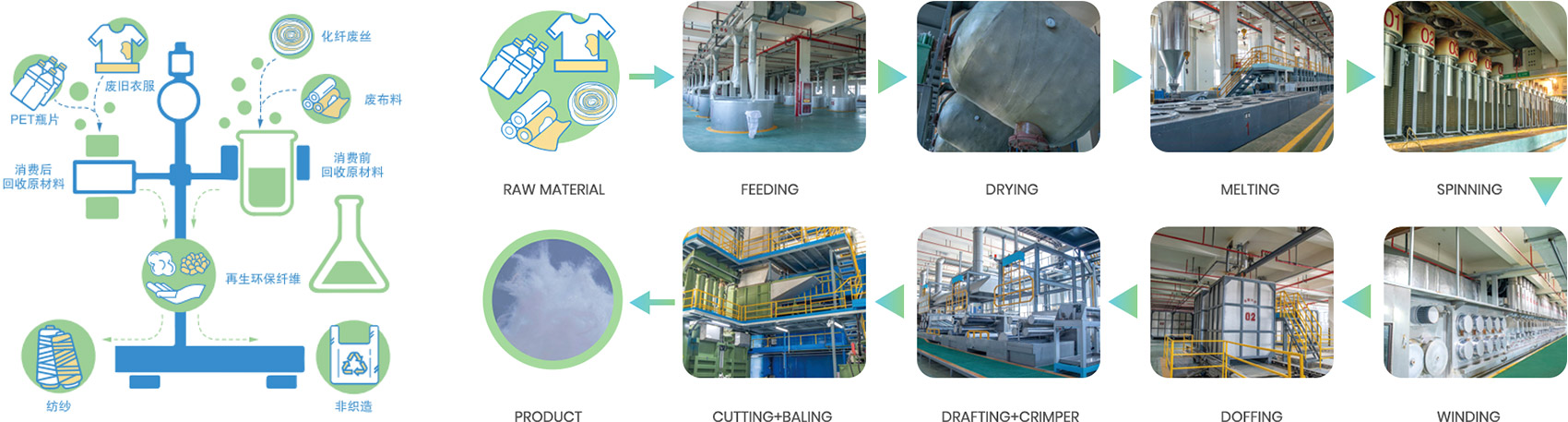

3. Resource recycling: efficient production of recycled polyester fiber

While pursuing high performance, Suzhou Emon New Material Technology Co., Ltd. also attaches great importance to sustainable development. The company makes full use of the abundant resources of local textile mills and local chemical fiber factories in the surrounding area, as well as recycled bottle flakes as raw materials, and achieves efficient production of recycled polyester fiber through advanced recycling and regeneration technology. This move not only reduces dependence on primary oil resources and production costs, but also effectively reduces environmental pollution and is in line with the global trend of green manufacturing.

Suzhou Emon New Material Technology Co., Ltd. relies on its profound accumulation and technological innovation in the field of modified fibers, which not only greatly improves the comprehensive performance of its products and meets the diversified needs of the market, but also demonstrates the company's corporate governance through the practice of resource recycling. Social responsibility. In the future, with the continuous advancement of material science and the continuous upgrading of consumer demand, Emon will continue to explore new boundaries of modified fibers and bring more surprises and possibilities to the textile industry.